What is single malt scotch whisky made of? The 3 + 3 Ingredients list.

Single malt scotch whisky is made of three main ingredients: malted barley, water, and yeast. These natural ingredients have been used in much the same ways for hundreds of years. And, where we're talking specifically about what single malt scotch whisky is made of, it has to be these three specific ingredients. You can't use, for example, grains other than malted barley.

Beyond these three main ingredients, there are three further factors at play. They don't meet the traditional definition of an 'ingredient', but they are key to developing a whisky's flavour. These are: oak casks, time, and peat.

Let's look at these ingredients in greater detail.

Malted barley used in making single malt scotch whisky

Malted barley is the source of sugar that the yeast consumes to produce alcohol. It is also one of the key contributors to flavour.

The type of barley used has changed over the years. This change is the result of farming, and developing crops that produce higher yields. In simple terms: more modern crops produce more grains, which means more sugar to create a greater amount of alcohol when fermented.

Heritage barley types

Heritage barley types used in the past include Oxbridge, Prisma, Chariot and Golden Promise. As lower-yield varieties, these are not commonly used today. However, as new artisan distilleries look for heritage crops to revive and experiment with, they may yet see a revival.

Current barley varieties

The most common varieties of barley used today are Belgravia, Concerto, Propino, Quench and Shuffle. The barley can be grown anywhere, the Scotch Whisky Association doesn't state that it has to be Scottish barley. That said, one of the emerging trends that artisan whisky distilleries are adopting to set themselves apart from the competition is to source their barley locally - even to grow it themselves. This "field to bottle" control and transparency helps create a unique, quality whisky.

Modern barley types

Modern barley varieties being experimented with in whisky include Moonshine, Odyssey, Chronicle and Overture. As farmers look for barley varieties that are sustainable, hardy, and high-yield, we can expect the types of barley to slowly evolve over time. More variety then gives distillers more choice as to what they use to make their whiskies.

Creating malted barley

Malted barley is created through a process known as 'malting'. The grains of barley are carefully dampened and laid out on a warm floor. They are then left to germinate - to start growing. As the grain of barley starts to grow, it begins breaking down its store of sugar. It is that sugar which feeds the yeast during the fermentation. Before the barley grows too much, its growth is stopped by heating the grain - and killing the germination. This ensures enough sugar is left for fermentation.

The role of water in making scotch whisky

Making whisky is a water-intensive process. You need a lot of water. So it's no coincidence that whisky distilleries are usually found near springs or rivers. Particularly historic distilleries. As an ingredient, water can be used at three key points in making whisky, during fermentation, before filling casks, and at bottling.

Using water to create wort

Added to the crushed malted barley to create a 'wash', which is then fermented into 'wort'. Wort is like a beer, which can then be distilled to create new make spirit, the starting point for single malt scotch whisky.

Adding water to new make before filling casks

Added to the new make distillate, to bring the ABV of the spirit down to an appropriate level for filling casks. Whether water is added, and if so how much is used, depends on the distillery's chosen filling strength. To give you a rough idea, new make spirit is usually around 68% ABV. Water can then be added to bring the spirit down to 63.5% before a cask is filled.

Adding water when bottling single malt whisky

Added to the matured single malt scotch whisky, before it is bottled. Most whiskies on the market are sold at a reduced bottling strength. 40% ABV is the strength you will see the most often. Mid-range strengths are 46-49%. But unless the whisky is bottled at natural cask strength, by definition at least some water has been added to bring the ABV down.

Sourcing water to use in making whisky

Because water is such a key ingredient in making single malt scotch whisky, where that water comes from can be a key consideration. Many distilleries will protect their water source, trying to gain exclusivity over it. It becomes part of their heritage, their story, and their marketing. For example, sister distilleries Glenfiddich and Balvenie who draw water from the Robbie Dhu springs.

The logic is that the minerals in the water will effect the fermentation process, influencing the flavour profile. Given the distillation process, and recognising the major impact the maturation phase, experts are divided on how important the water source truly is. But certainly purists will argue it is at least one of the variables in creating flavour.

Types of yeast used in making scotch whiskies

Yeast is a fungus. A friendly fungus - humans have used yeast for thousands and thousands of years. It plays a key part in making bread. And, it plays a key part in making alcohol. From beer and cider, to wine, and to whisky - yeast is crucial.

You don't need to add a lot of yeast. Around 2 to 2.5% of the wash volume will be enough for the magic to happen. Once added, the yeast feeds off the sugars present in the malt barley wash to create alcohol and flavour compounds during fermentation. The yeast used during fermentation needs to be able to:

- Convert sugar into alcohol (ethanol) efficiently

- Create desirable flavours

- Survive long enough in a hot, high ethanol and high sugar environment to complete their crucial work

- And, remain stable during storage before use

All the types of yeast used in making whisky come from one species: Saccharomyces Cerevisiae. There are different types of yeast that distillers can choose to use, within this species. Most distillers will use a combination of two styles: brewer yeasts and distillers yeasts. By using a combination of the two, they can ensure they use all the sugar in the wash (maximising alcohol) while also producing desirable flavours.

The role of wooden oak casks in making scotch whisky

Fermentation is when a whisky is born. Distillation is where a whisky gains its strength and clarity. But maturation is where the whisky's flavours fully develop.

After distillation, a whisky is clear and colourless. It does have flavour and aroma, and high-quality new make spirit can be delicious. But, put side by side with an aged whisky, it won't have the same depth and breadth of flavour. And, it may be less refined - with more prickle and alcohol heat.

The maturation phase adds flavour, broadens dimensions, and smooths any rough edges. And this maturation phase happens in wooden barrels. The Scotch Whisky Authority regulates that these have to be specifically oak casks. But a range of sizes and types of whisky cask are allowed.

There are two main species of oak used in scotch whisky casks. American oak, Quercus Alba, and European oak, Quercus Rober or Quercus Patraea. American oak softens whisky, and adds notes of vanilla and a creamy character. European oak has a greater wood flavour, with added spice and a dry character.

Looking briefly beyond Scotch whisky, other woods are used. Mizunara oak, Quercus Mongolica, is prized for Japanese whisky. And yes, woods other than oak can be used. Not for scotch whisky, but for other categories. Method and Madness in Ireland have used a wide range of weird and wonderful woods for their Irish whiskey, for example chestnut.

You could well argue that the oak casks aren't so much an ingredient as they are a tool for making whisky. And I'd see what you meant by this nuance. However, I include it in the ingredients list as it does play a more active roll in developing flavour than one may think.

As the whisky interacts with the wood a series of chemical exchanges happen. Some chemicals are removed from the whisky. Some are added. And some interact, developing new flavours. Let's take one example: the vanilla note you'll find in a lot of whiskies (particularly American whiskey). This flavour comes not from the malted barley, water or yeast. It's not created during fermentation or distillation. Instead, it comes from vanillin, a molecule found in wood, which is absorbed into the whisky during maturation. And if you're wondering why this vanilla flavour is particularly prominent in American whiskey, this is because the oak casks used are first fill - and so the effect is stronger.

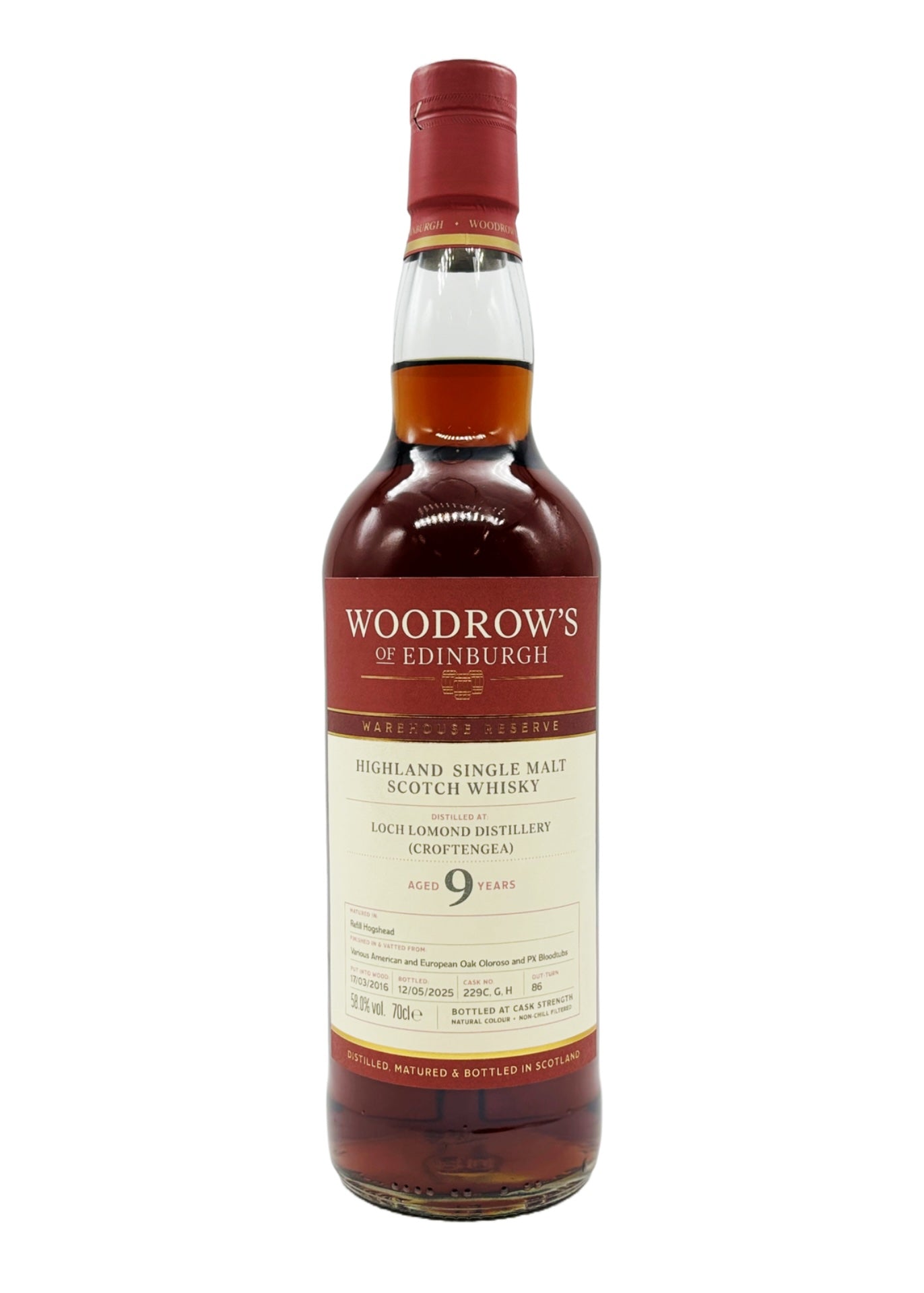

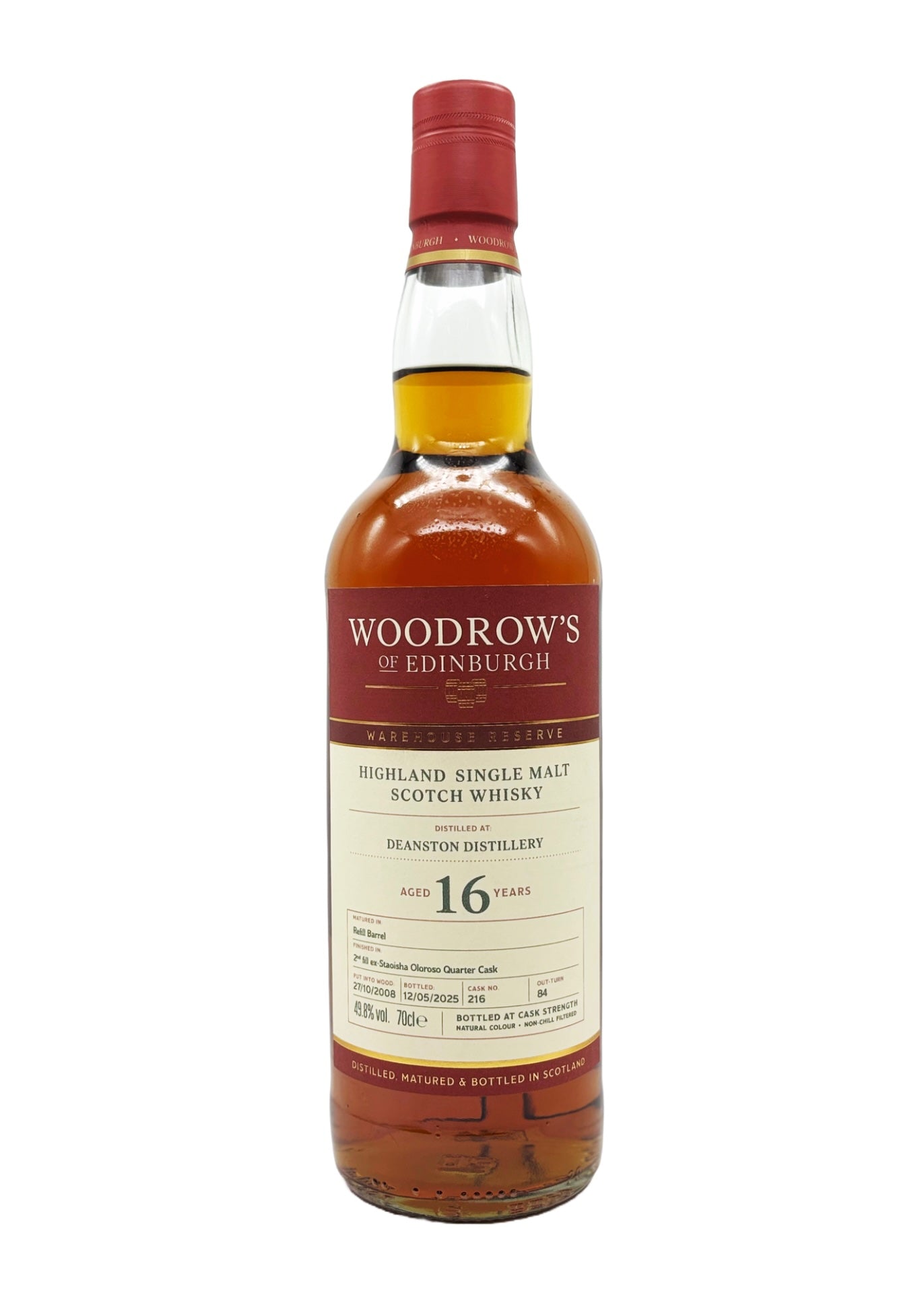

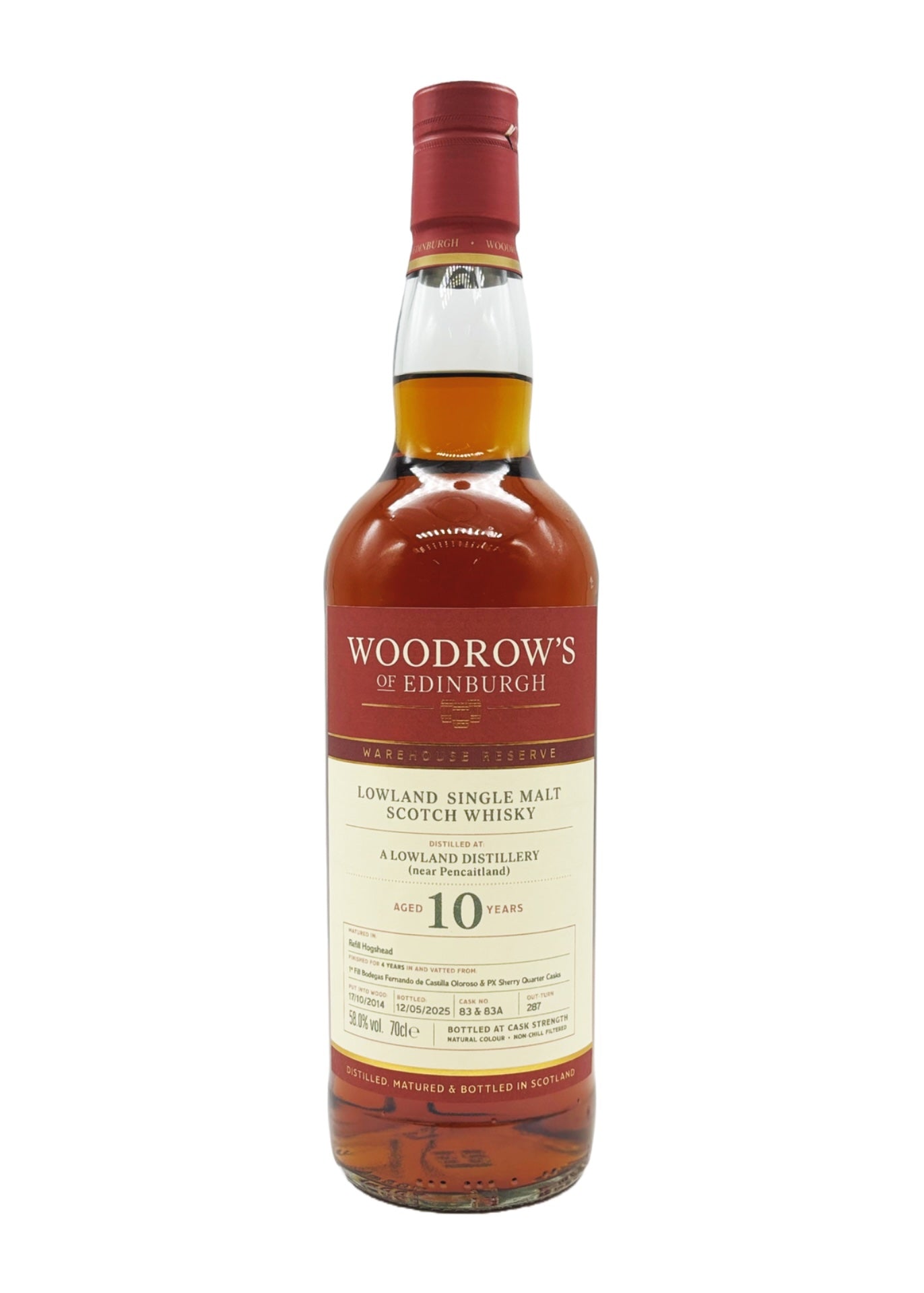

The oak casks used in making single malt scotch whisky often held something else, before the whisky was added. Often, that was American whiskey - as oak casks are a common byproduct of making American whiskeys. But it can also be other drinks. You can read about the use of sherry casks in making whisky here, and about the use of port casks in making whisky here.

Making single malt scotch whisky takes time

So, if I was stretching the definition of 'ingredients' with the oak casks above, I'm definitely breaking it with this one. But, let me explain. Developing flavour while aging in oak casks takes time. Lots of time. The Scotch Whisky Authority states that a scotch has to be aged for a minimum of three years. But, in reality, many whiskies are aged for much longer than three years. Think about the age statements that you may find in a supermarket: I bet you'll often see '12 Years Old'. And a whisky can go up to 30 years, 40 years, or even older.

So, time plays a key role in making flavour. You have to be patient and let the oak cask work its magic over time. And, given how the length of time the cask is left to age has such a material impact, this is why I include time in this list.

The use of peat in making smokey whiskies

Peat is centuries-old vegetation that has part-decayed and part-survived. It becomes compressed over hundreds of years, into a kind of fibrous dense soil, thick with that old vegetation. It can be cut into brick shapes and then dried.

Peat has long been used as a source of fuel. In Scotland and Ireland in particular, it was burned to provide heat to cook with, boil water with, and keep the home warm. And, peat is sometimes used in making whisky.

It's important to note that not all scotch whiskies are made using peat. Only some. Where it is used, peat is burned to create heat which dries the malted barley, stopping it from growing, and keeping the sugar locked in the grains.

During this process, the peat gives off smoke. Picture that fibrous vegetal soil brick I described, burning on a fire. I bet you can imagine the smoke coming off it. That smoke will gently permeate the drying grains of barley. And some of the smoke particles will remain in the grains, through fermentation and distillation, and into the whisky. This adds a smokey earthy character to the final single malt whisky.

So again, not a typical ingredient, and not a ubiquitous one. But, peat can be used to add an extra flavour dimension to whiskies.

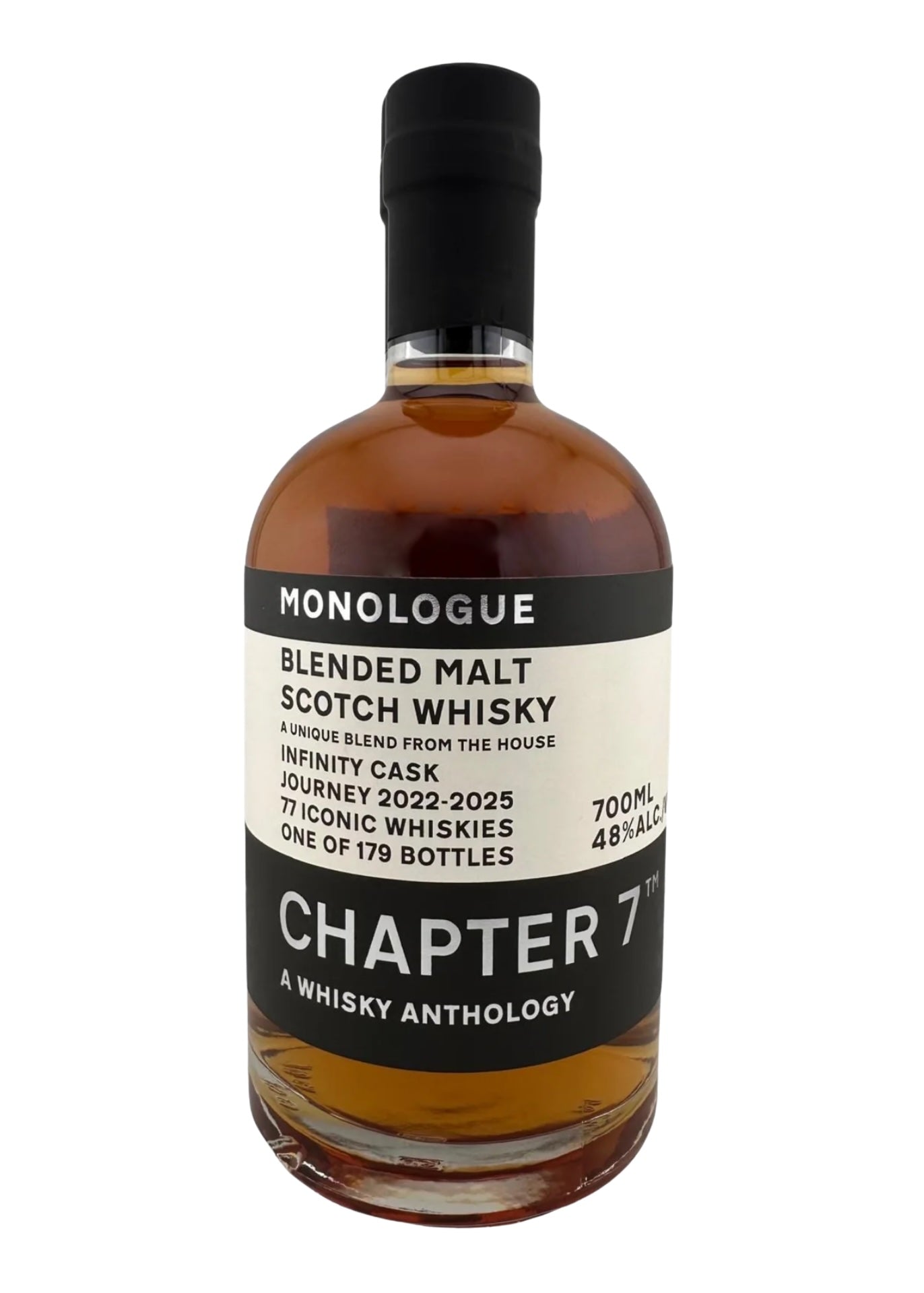

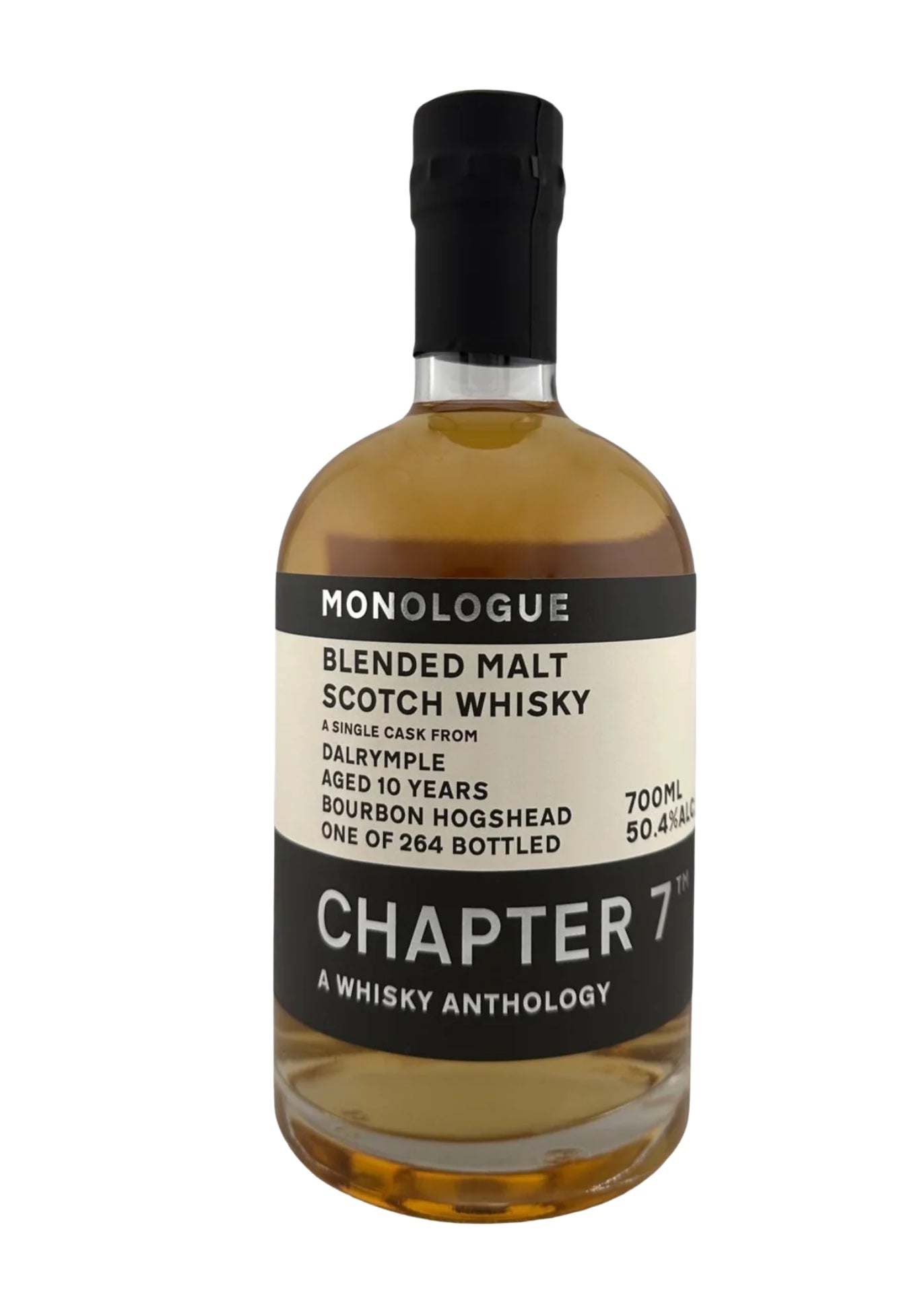

Feeling thirsty?

I hope you've enjoyed this article about the ingredients whisky is made of. If you're feeling thirsty, I have a great selection of single malt scotch whiskies available here. They're all from small independent brands, who are passionate about artisan whiskies made using the very best ingredients.

And, if you enjoyed this article, you may enjoy reading my article about the chemistry of whisky here.

Thanks for reading, Ed

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.